|

Royal Construction Inc.

|

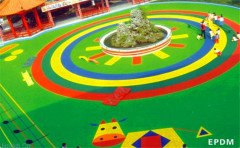

Environment-friendly Pervious no fines porous Concrete Pavement With good water permeability

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Pervious concrete is a special type of concrete with a high porosity used for concrete flatwork applications that allows water from precipitation

Pervious concrete is a special type of concrete with a high porosity used for concrete flatwork applications that allows water from precipitation and other sources to pass directly through, thereby reducing the runoff from a site and allowing groundwater recharge.

Pervious concrete is made using large aggregates with little to no fine aggregates. The concrete paste then coats the aggregates and allows water to pass through the concrete slab. Pervious concrete is traditionally used in parking areas, areas with light traffic, residential streets, pedestrian walkways, and greenhouses.It is an important application for sustainable construction and is one of many low impact development techniques used by builders to protect water quality.Pervious concrete pavement is a unique and effective means to address important environmental issues and support green, sustainable growth. By capturing stormwater and allowing it to seep into the ground, porous concrete is instrumental in recharging groundwater, reducing stormwater runoff, and meeting U.S. Environmental Protection Agency (EPA) stormwater regulations. In fact, the use of pervious concrete is among the Best Management Practices (BMPs) recommended by the EPA—and by other agencies and geotechnical engineers across the country—for the management of stormwater runoff on a regional and local basis. This pavement technology creates more efficient land use by eliminating the need for retention ponds, swales, and other stormwater management devices. In doing so, pervious concrete has the ability to lower overall project costs on a first-cost basis.

In pervious concrete, carefully controlled amounts of water and cementitious materials are used to create a paste that forms a thick coating around aggregate particles. A pervious concrete mixture contains little or no sand, creating a substantial void content. Using sufficient paste to coat and bind the aggregate particles together creates a system of highly permeable, interconnected voids that drains quickly. Typically, between 15% and 25% voids are achieved in the hardened concrete, and flow rates for water through pervious concrete are typically around 480 in./hr (0.34 cm/s, which is 5 gal/ft²/ min or 200 L/m²/min), although they can be much higher. Both the low mortar content and high porosity also reduce strength compared to conventional concrete mixtures, but sufficient strength for many applications is readily achieved.

While pervious concrete can be used for a surprising number of applications, its primary use is in pavement. This site focuses on the pavement applications of the material, which also has been referred to as porous concrete, permeable concrete, no-fines concrete, gap-graded concrete, and enhanced-porosity concrete.